咨询热线 15388025079

咨询热线 15388025079 时间:2021-12-29 21:49:21 浏览量:727

What is M2M? What is the difference between M2M communication technology and the Internet of Things?

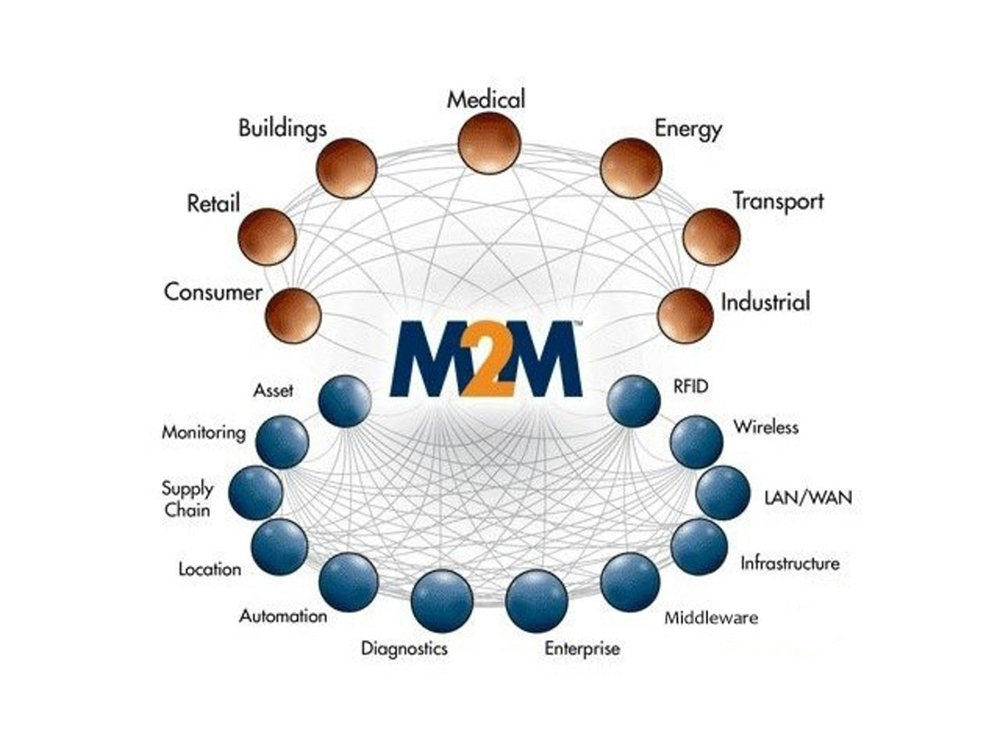

M2M (MachinetoMachine) is the effective control of equipment through mobile communication, thereby greatly expanding the boundaries of business or creating a more efficient operation method than traditional methods or creating new services that are completely different from traditional methods. In short, M2M refers to the exchange and transmission of information between machines, and the concept of information sharing is achieved through the transmission and link of network and machine equipment communication.

Actually, as early as 2002, the concept of M2M business had been proposed, but due to the immature communication technology, the development was still in the enlightenment stage, such as tap water, automatic meter reading by power companies, and digital home applications. With the rapid development of wireless communication technology, M2M application services have entered a stage of rapid development. M2M applications can be seen in agriculture, industry, public safety, urban management, medical care, mass transportation and environmental monitoring, such as: wisdom The integration of these services and applications, such as energy conservation, smart vehicles, smart medical care, smart cities, and smart logistics, relies heavily on the development of M2M technology.

M2M (Machine to Machine) is a machine-to-machine communication technology, in a broad sense, M2M (Man to Machine), the Internet of Things is to connect objects (including machines) together. Obviously, M2M is an important part of the Internet of Things to connect objects. It is impossible to connect objects to form a huge Internet of Things without M2M technology. M2M technology and products are important technologies and products that constitute the network layer of the Internet of Things.

M2M is an important part of the Internet of Things, and on the basis of the success of the M2M market and products, a series of products and application solutions for the Internet of Things industry chain should be actively developed. Not only to provide customers with M2M products, but to provide a complete set of IoT products covering sensors, IoT terminals, network equipment and application platforms based on M2M based on the combination of upstream and downstream manufacturers; at the same time, based on the complete set of IoT products, according to the user’s Actual application requirements, develop and customize IoT application solutions for users and provide turnkey engineering services. My development strategy in the Internet of Things industry is: if others have, have advantages, and are stronger than us, we will join forces. We develop and produce products that are not in the industry chain by ourselves, so as to provide users with serialized and standardized products and overall solutions that meet application needs.

Industrial applications of M2M communication technology:

In the field of application, M2M module technology often combines sensors to collect information, and through the sensor to explore the unknown environment, the obtained information is transmitted to the device or equipment, and the information that can be analyzed has been provided. In the industry, the quality of products can be ensured through the collection of real-time report information, and problems such as failure of old equipment parts can be avoided. According to the required purpose, the information needed will be explored, the accuracy of the environment will be improved, and the safety of people's lives will also be improved.

For example, M2M combined with sensors, applied to industrial process monitoring, can help the machine reduce downtime to diagnose potential problems in a timely manner, and provide timely notification and warning if a malfunction occurs before affecting the operation of the machine. Improve machine efficiency by monitoring machine performance and making appropriate adjustments. At the same time, it also reduces maintenance costs and increases the number of equipment produced. Because of understanding and immediate response, information, communication and calculations can be obtained at any time.

In the factory's product manufacturing process and the maintenance of automated processes, it is an indispensable role. Since most of the machines in the factory will inevitably encounter defects and the possibility of looseness, process monitoring and adjustment are used to avoid machines, which reduce productivity due to defects and looseness. The information can be controlled through the collection of instant messages reported, and the data can be traced through access and file creation, which facilitates the grasp of the life cycle of machines and products.

上一页:Wireless data transmission module

下一页:Principle of LoRa Frequency Hopping Spread Spectrum Communication (FHSS)

相关推荐

相关产品